Trolley Assemblies / Hardware

For the most part, this is simply a picture page illustrating (1) JMI AC100 SDL mounting hardware and assemblies, and (2) the differences between JMI trolleys and similar looking trolleys produced by Thomas Organ for US-made solid state Super Beatle speaker cabinets.

At present, no JMI engineering/mechanical drawings are known to survive either for the SDL speaker cabinet or its trolley. It is to be hoped that something pertinent eventually comes to light.

JMI late 1964 to 1967

Cabinet mount, SDL cabinet from summer 1965. Dimensions: diameter 3"; body 1" tall, 1 7/8" diameter; threaded centre 1 1/2" tall; thread diameter 3/8" (British Standard Whitworth).

Mounts were initially (late 1964 to mid 1966) attached to the sides of the cabinet with flat-headed 3/4" Number 8 wood screws, as in the example pictured above. Later, cabs were made with pre-drilled holes in their sides so that 1 1/4"and 2" 2BA machine screws could be used, secured inside with washers (one flat and one grip washer) and a nut.

Friction washers for the assembly were of two types: rough fibre (the most common type) or translucent nylon. These slotted over the central drum of the mount, lying flush against its outer rim. In 1967 metal washers were sometimes used instead of fibre or nylon.

Dimensions of the washer on the left: diameter 2 15/16"; width 1/2" to 9/16".

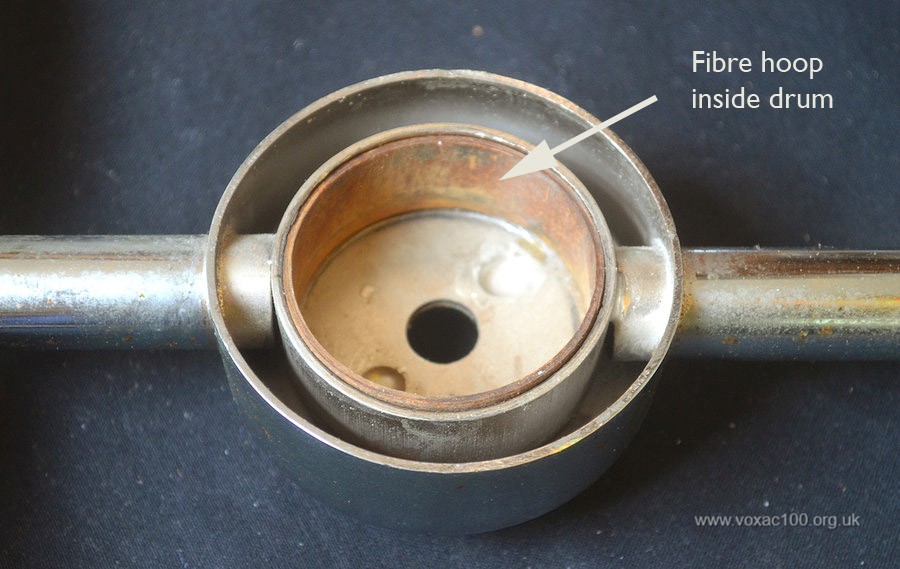

The drum of cabinet mount slotted inside the inner drum of the trolley's side mount. Inside the inner drum of the side mount, a loose resin-hardened fibre hoop was provided, capable of revolving freely. When the cab was angled backwards in its trolley, a handwheel locked the drum tight against the friction washer.

Inner diameter of inner drum 2"; fibre hoop 1/16" thick.

Standard JMI enclosed receptacle for the mount on the trolley side.

On the left below, a standard JMI hand-wheel (as used from mid 1964 through to early 1968); on the right, a battle-scarred example of the Thomas Organ version. JMI impressed the logo into the metal; Thomas Organ incised it.

JMI left; Thomas Organ right.

JMI left; Thomas Organ right.

Just to say in passing, that JMI trolleys are beautifully made, the welding at the junctions of the members particularly fine. Repro trolleys (of which there are now a few) are alas less than stellar in this respect. One can always spot them by their globbed, piled up welds.

Thomas Organ 1966 - 1971

One of the easiest ways of identifying an American-made trolley is by its castors, which have pronounced hoods. JMI castors are slightly smaller and have simple metal forks. Also worth noting is that the American assemblies have stems of 1/2" diameter. JMI's are 7/16".

On the left, Thomas Organ; to the right, English.

Although the general format of the Thomas Super Beatle trolley was much the same as JMI's SDL trolley, there are differences, notably the cabinet mounting point.

Thomas Organ Super Beatle trolley.

Below, the mounting hardware from a Super Beatle trolley. The cabinet mounts are simple metal discs with a welded thread. The plain metal disc sits between the hand-wheel and the frame.

Swivel wheel hardware from a US-made Super Beatle trolley of 1967 - with distinctively American plain metal friction discs - on top of a JMI AC100 cab.

Schema produced by Thomas Organ for the third version of the Super Beatle - V-1143.